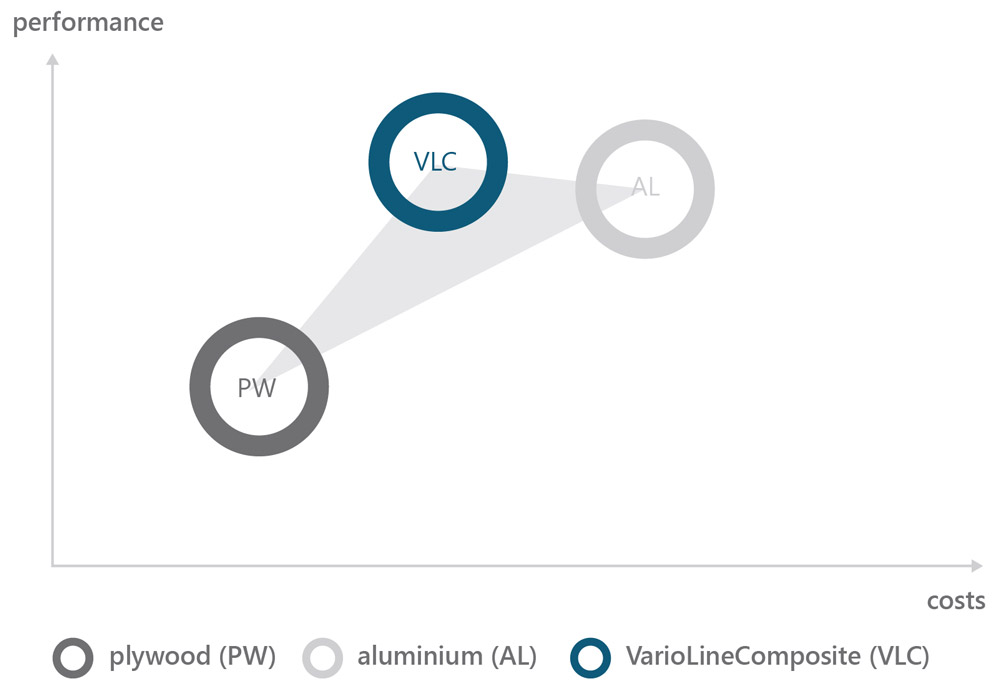

The two most important criteria in relation to scaffolding elements are high safety and low weight. Every gram makes a difference when you transport the elements, and of course even more so when you erect and dismantle the scaffolding. Lighter scaffolding elements made from our VarioLineComposites (VLCs) save energy, time and money. Working on scaffolding holds many dangers. For this reason, everyone involved needs to be absolutely certain that the scaffolding floor will hold the weight safely and permanently.

Thanks to their composite structure, our scaffolding elements have lasting reserves in terms of stability and grip – avoiding some precarious situations. When work has finished on the scaffolding, the composite elements can generally be cleaned easily with a pressure washer, quickly making them ready for use again. As we all know, short servicing times mean longer usage times and greater economic efficiency. A plus that pays off for everyone.

VarioLineComposites stand for:

- Adjustable to any scaffolding system and adaptable in terms of operational weight, energy absorption / safety, durability / total costs.

- Components with no glued joints or other weak points.

- Fit perfectly into your existing cost-effective tubing and replace existing scaffolding elements 1:1.

- Upgrade your existing production lines and minimise your time to market and re-erection costs.

- Elements you can rely upon – with a zero failure rate so far, making them a safe investment.

- Easy to clean.

- Replace aluminium – without its disadvantages.

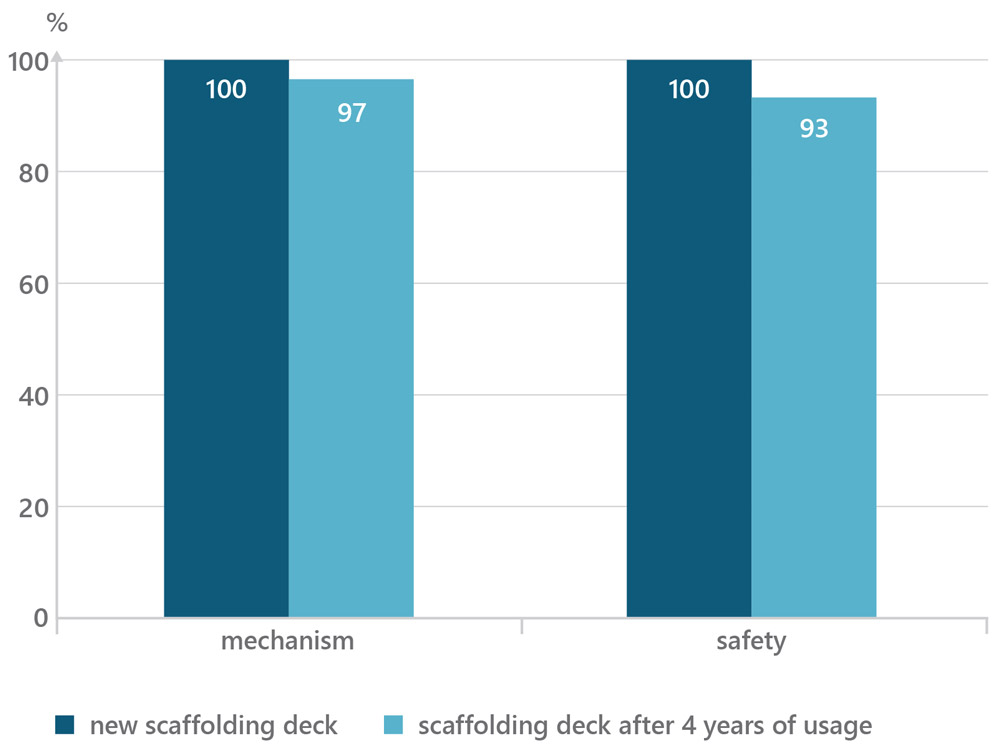

Even after years of use, VarioLineComposites still come out well, with no more than superficial damage to their surface, structure or even their rivet holes. We also check their mechanical data in the lab, and even these show hardly any change (see diagram below).

VarioLineComposite scaffolding elements can be added to your system as you need them*:

- Different combinations of core and substrata from our modular system

- Component thickness can be adjusted to almost any width between 9 and 21 mm

- Wide range of colours for top and underside (e.g. in your company colours)

- Permanently heat-stamped with serial number

- Tailored to meet your requirements (walkboards, access doors, covers, etc.)

- Packaging and logistics by request

* if volume of order is sufficient

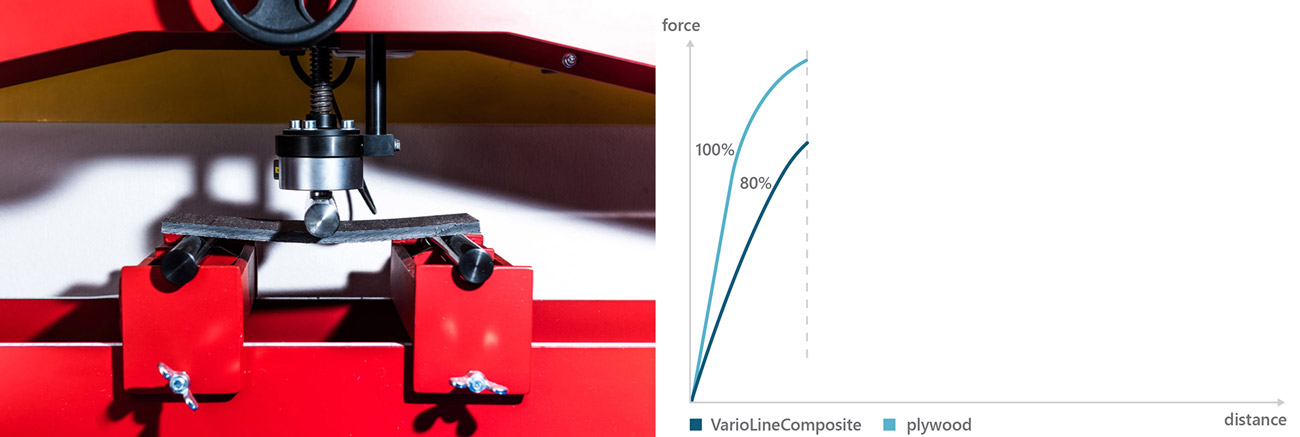

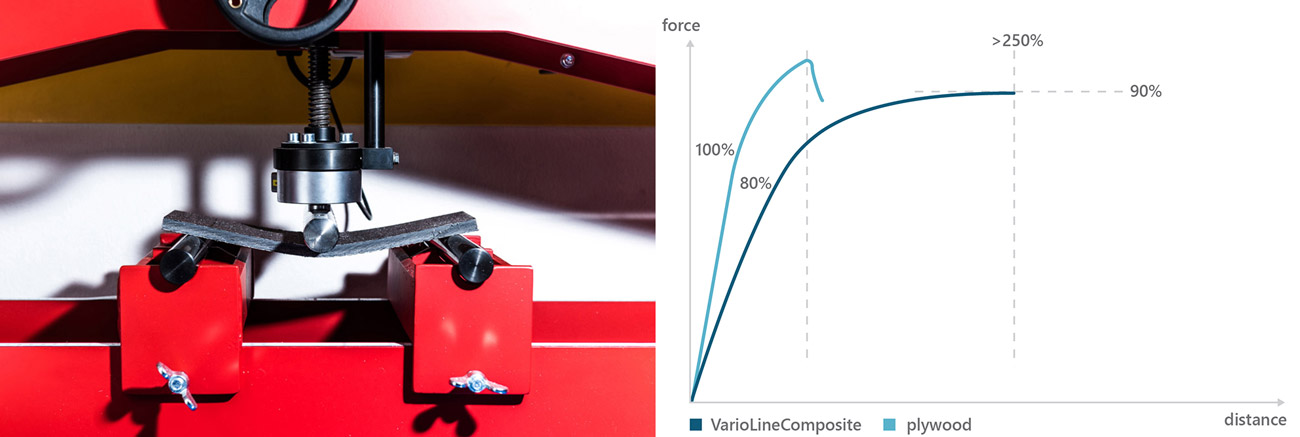

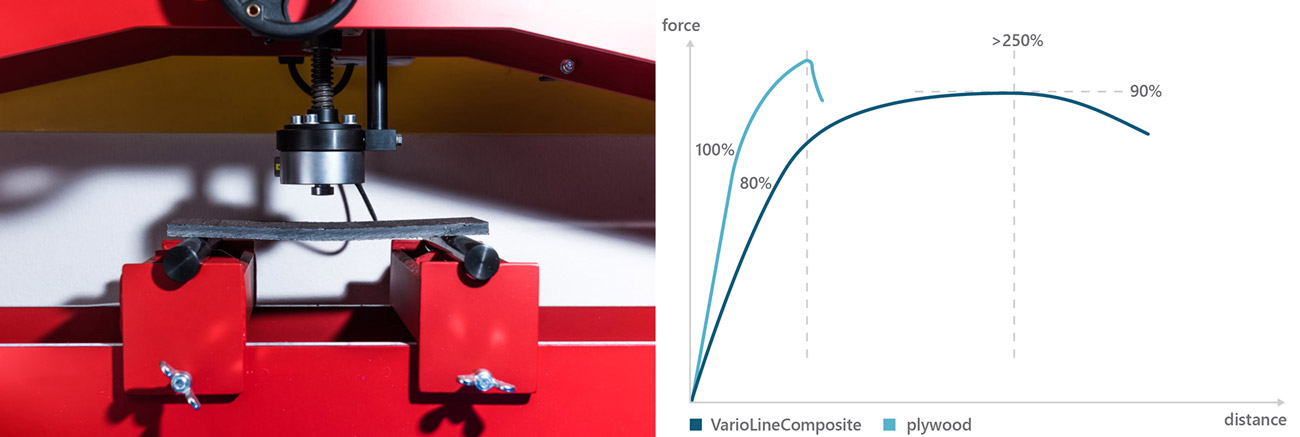

Bending test with 2,000 N

Laboratory bend tests show how VarioLineComposites act under successively rising loads, demonstrating how the energy absorption develops. This is crucial for structural safety. The result: VarioLineComposites stand out for their extremely high energy absorption without breaking (no catastrophic failure). Both are important factors for high safety levels.

PolymerPark – ADVANCING WITH COMPOSITES

For more information about our scaffolding elements, please contact our sales division:

☏ +49 351 89 99 12 – 10

✉ sales@polymer-park.com