More safety on the construction site

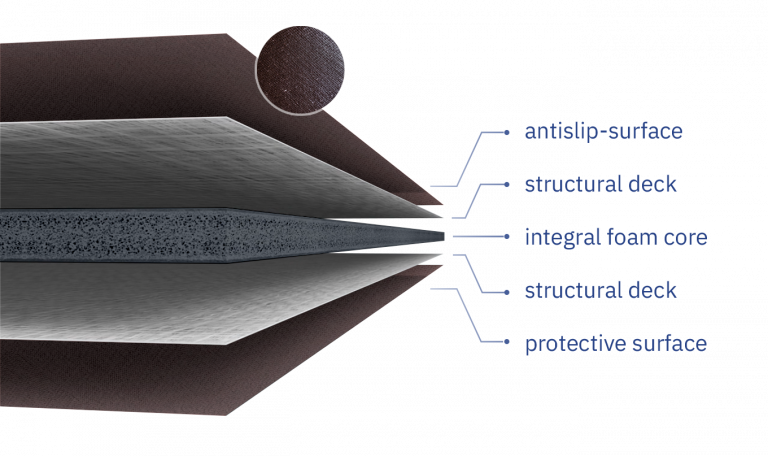

PolymerPark's composite scaffolding decks offer high levels of safety and are extremely durable. Their properties remain consistent even after 10 years, with no hidden defects.

The energy absorption is five times higher than conventional plywood decks, and even under excessive loads, they do not collapse in total failure. The decks have been extensively tested by national certification authorities (e.g., DIBT in Germany).