Impressive lifespan

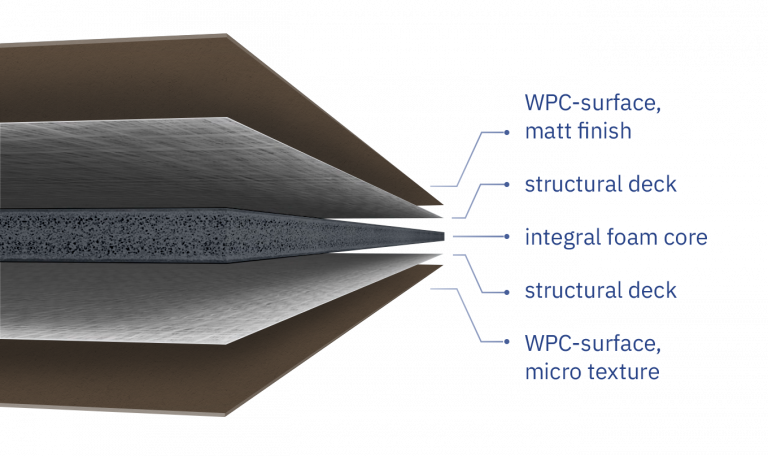

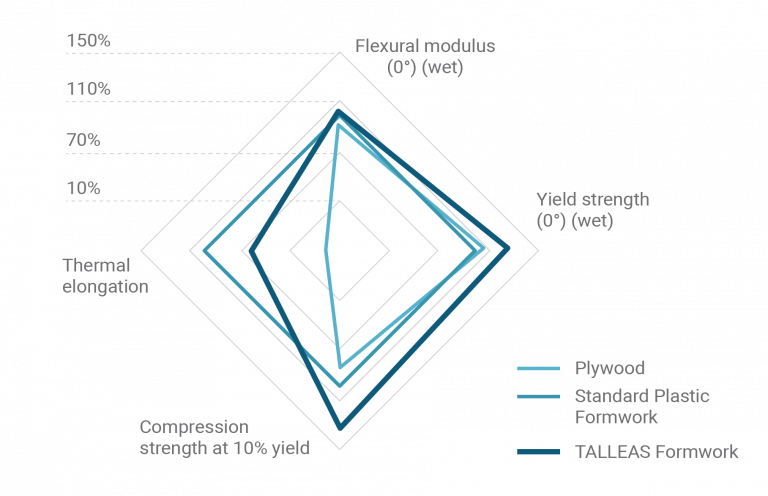

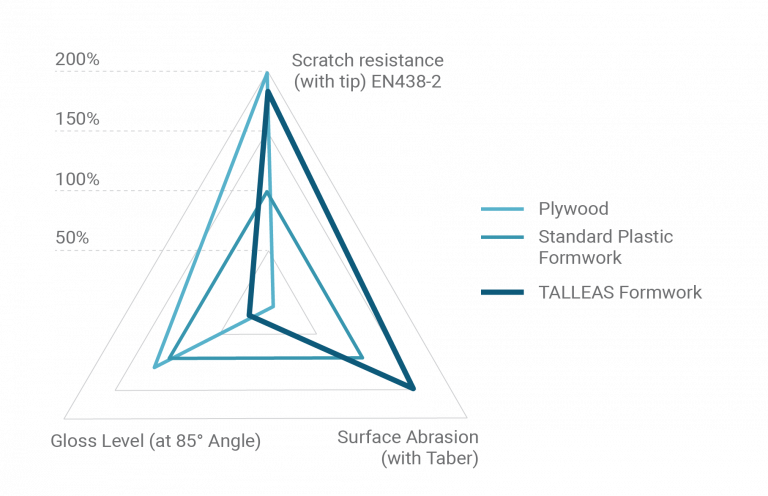

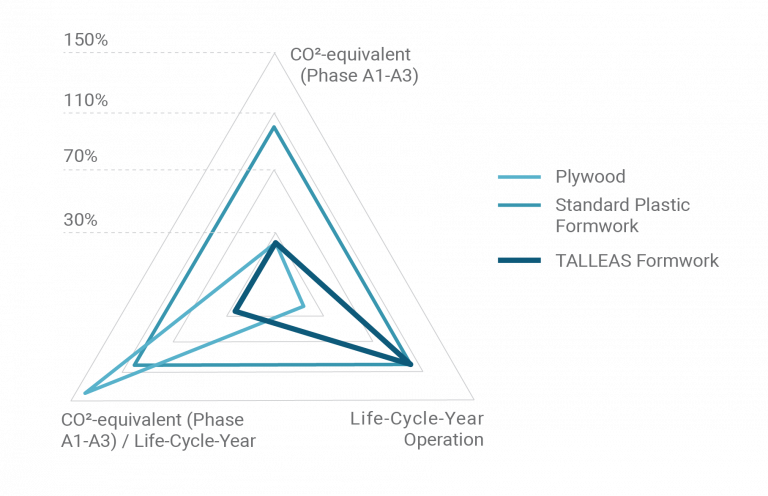

TALLEAS formwork panels are robust, water-resistant, and retain their properties over long periods of use. The market-proven WPC surface is scratch- and abrasion-resistant, ensuring a durable, high-quality concrete surface. TALLEAS formwork has a lifecycle 4-6 times longer than plywood—a significant contribution to both cost-effectiveness and sustainability.